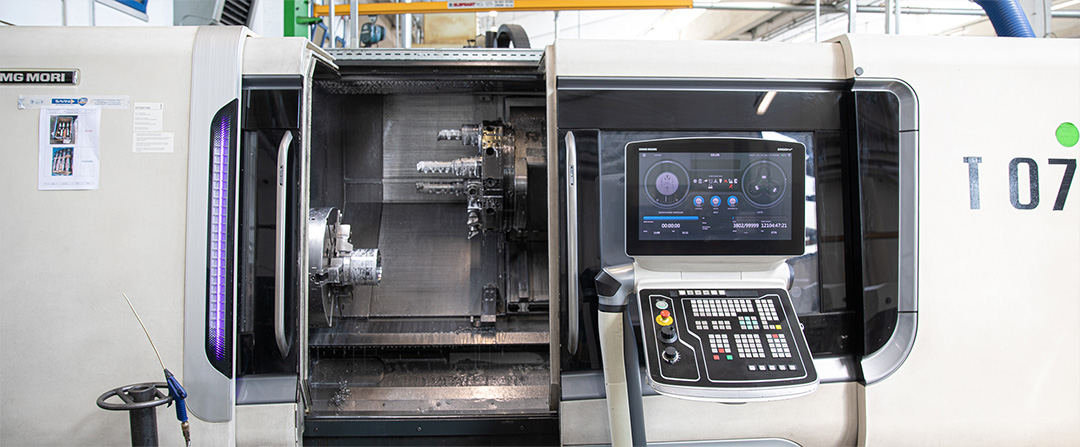

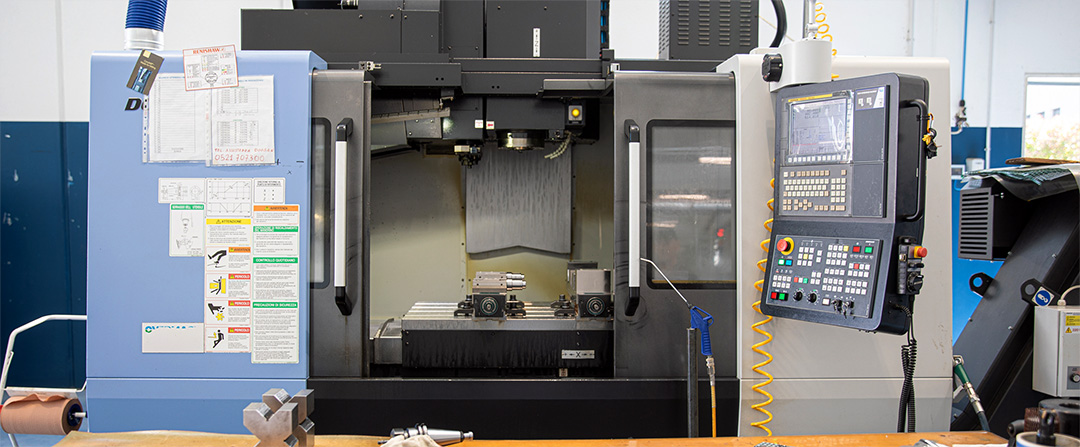

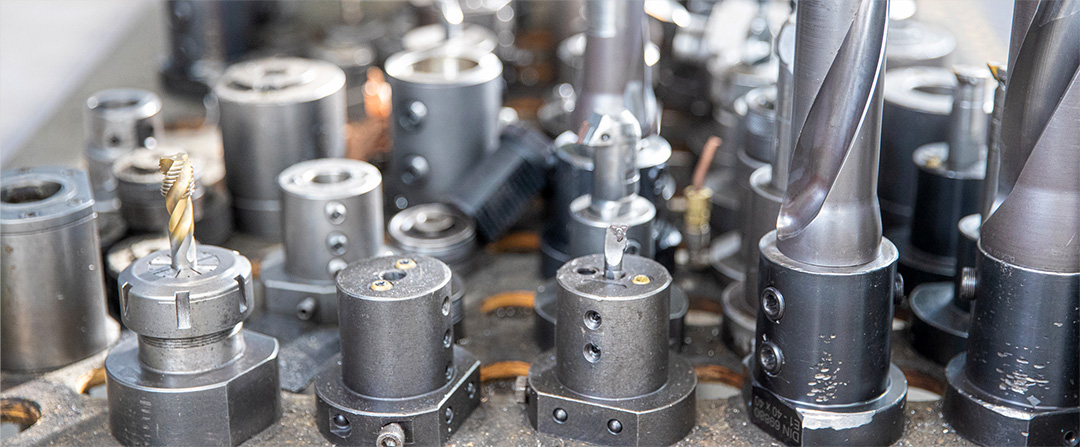

In order to maintain its production standards to the highest level of excellence, Torneria Savini has invested in state-of-the-art machinery, operated with the utmost expertise by technicians who are always kept up-to-date with the latest professional developments in the sector.

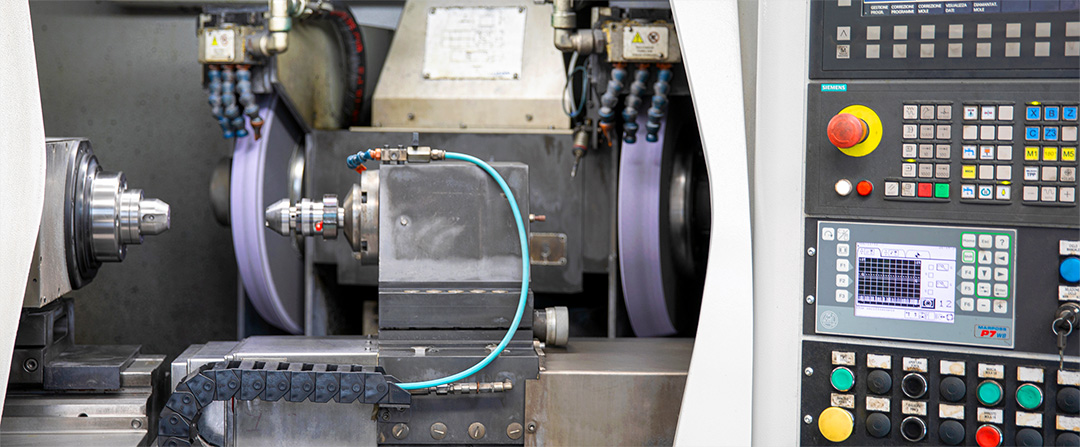

All CNC lathes are equipped with motorised tools and C-axis on spindles, capable of drilling, threading and milling.

All machining operations are also subjected to rigorous surface quality checks using the most advanced measuring instruments, such as the Zeiss Three-Dimensional check and the state-of-the-art CNC Profilometer.

Torneria Savini's CNC Machinery and Quality Control

FINISHING/SECONDARY LATHES

BAR LATHES

PARALLEL LATHES

5-AXIS LATHES

SLOTTING MACHINES

BROACHING MACHINES

AUTOMATED VERTICAL TURNING CENTRES

MACHINING CENTRES TO FACILITATE OTHER MACHINING OPERATIONS

GRINDING MACHINES

QUALITY CONTROL ROOMS